-

-

-

- Acetylacetone peroxide

- Benzoyl peroxide (BPO)

- Cumene Hydroperoxide (CHP)

- Cumyl peroxyneodecanoate

- Cyclohexanone peroxide

- Di(2,4-dichlorobenzoyl) peroxide

- Dibutyl peroxydicarbonate

- Dicumyl peroxide (DCP)

- Dihexadecyl peroxydicarbonate

- Diisobutyryl peroxide

- Diisopropyl peroxydicarbonate (BIPB)

- Diisopropylbenzene hydroperoxide

- Dilauroyl Peroxide (DLP)

- Di-tert-butyl peroxide (DTBP)

- Ditetradecyl peroxydicarbonate

- Methyl Ethyl Ketone Peroxide (MEKP)

- Methyl isobutyl ketone peroxide

- Pivalate Peroxypivalate

- Tert-Butyl Cumene Peroxide

- Tert-Butyl Perbenzoate (TBPB)

- Tert-Butyl Peroxy-2-Ethylhexanoate (TBPEH or TBEC)

- Tert-Butyl Peroxyacetate (TBPA)

- Tert-Butyl Peroxyisobutyrate

- Tert-Butyl Peroxypivalate (TBPPI)

- Tert-Butylperoxy-3,5,5-trimethylhexanoate (TBPIN)

-

-

-

- Aromatics Production Catalyst

- Toluene Production Catalyst

- Methanol Synthesis Catalyst

- Formaldehyde & DME Synthesis

- Propylene Oxide Catalyst

- Ethylene Oxide Catalyst

- Sulfuric Acid Catalyst

- Ammonia Synthesis Catalyst

- Polyethylene Catalyst

- Polypropylene Catalyst

- Isomerization Catalyst

- Hydrogenation/Dehydrogenation

- Reforming

- Alkylation

- Tail Gas Treating Catalyst

- PET/PTA Catalyst

-

-

-

Products

Products

Products

FR-130

- Product Description

-

- Commodity name: FR-130

Polystyrene (PS) & Expandable Polystyrene (EPS): Improves fire resistance in insulation boards, packaging materials, and construction applications. High-Impact Polystyrene (HIPS): Used in electronics housings, appliances, and consumer products. Polypropylene (PP) & Polyethylene (PE): Sometimes modified for flame retardancy in wires, cables, and automotive parts.

Chemical Name:FR-130

Shape:Typically, available as a white to off-white crystalline powder or granules.

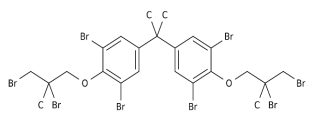

Component:1.1'-(isopropylidene)bis[3.5-dibromo-4-(2.3-dibromo-2-methylpropoxy)benzene]

Other names:Brominated Polystyrene (BrPS), Polybromostyrene

Molecular Formula: C23H24Br8O2

Molecular Weight: 971.67

CAS Number: 97416-84-7

Application:

Polystyrene (PS) & Expandable Polystyrene (EPS): Improves fire resistance in insulation boards, packaging materials, and construction applications.

High-Impact Polystyrene (HIPS): Used in electronics housings, appliances, and consumer products.

Polypropylene (PP) & Polyethylene (PE): Sometimes modified for flame retardancy in wires, cables, and automotive parts.

Brominated compound: Works synergistically with antimony trioxide (Sb₂O₃) for effective flame inhibition.

Thermal stability: Suitable for processing at typical polymer extrusion/molding temperatures.

Good compatibility: Disperses well in polystyrene and related polymers.

Packing:

25. 500 or 1000 kg bags

Storage:

Keep away from moisture, heat, and direct sunlight.

Recommended storage temperature: below 30°C (86°F).

Shelf life: Typically, 2 years if stored properly.

Keywords: FR-130

Related Products

Product Message

* Note: Please be sure to fill in the information accurately and keep the communication open. We will contact you as soon as possible.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

WhatsApp (Nancy):8618596185099

WhatsApp (Bella):8613255519601

E-mail:Md@silver-chem.cn

Email:Info@silver-chem.cn

Phone (WeChat):+86-13255519601

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home